KOWALSKI

Technical Specifications

-

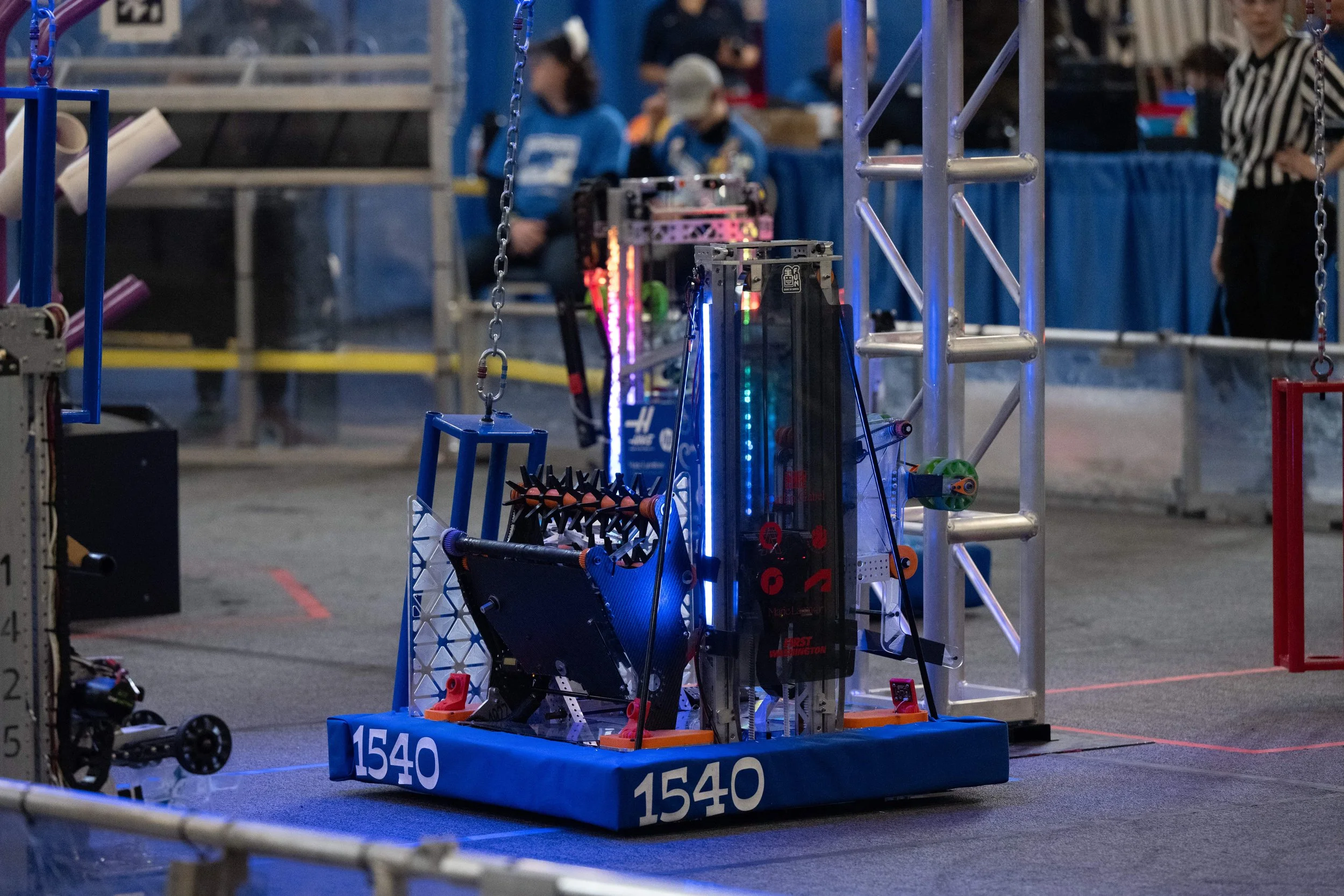

SDS Mk4n swerve modules with Kraken x60 driving motors, Falcon 500 turning motors

L1+ gearing for fast acceleration, top speed 14.2 ft/s, running FOC (Field Oriented Control) for steering and driving

Modules raised to lower the chassis by 7/8"

30” x 29.5” thickstock aluminum frame

0.090” lightened aluminum bellypan, pattern allows for easy wire routing

Bumpers utilize floor tiles and birch plywood backing for better impact absorption and durability, quickly removable with quick-release pi

-

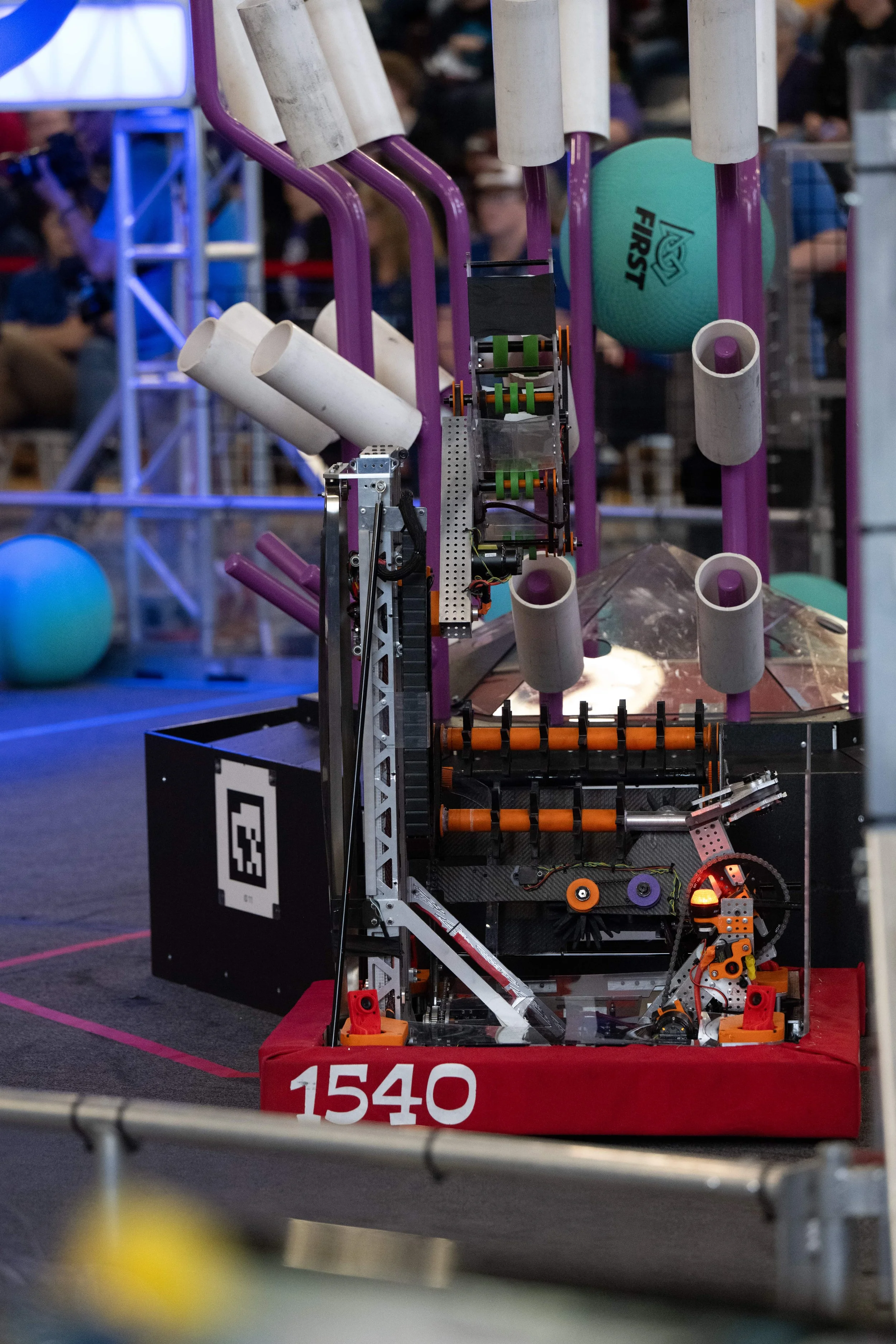

Compactly packaged dead axle pivot with pivot plate for quick replacements, 18:1 gearing for fast deployment powered by a single Falcon 500

Direct L1 scoring or handoff to end effector

Intake coral from ground or feeder station

Dead axle rollers with 60A star wheels powered by a Falcon 500

Passive side-wall funneling

-

Gearbox with cam belt tensioning system and coaxial constant force spring integration tightly packaged within the elevator carriage

Wires route through the axle for neat, well-protected wire run

Plates heavily lightened for weight reduction

1” OD dead axle shaft, power transferred through custom-machined gears

Modular with easy removal via a snap ring

Powered by a Kraken X60 with 28:1 reduction

Directly geared off-axis CANcoder for precise absolute positioning

Backlash reduction using shim tape and Loctite 680

-

Pocketed polycarbonate plates for siding with thinner polycarbonate plates for the top and bottom

Extended bottom plate for better control of coral when scoring

Four active rollers with 2” compliant wheels on ⅜” hex shafts for additional weight reduction

One ½” roller with 4” compliant wheels to grip algae against a static backing

Two laserCAN time-of-flight sensors to sense location/intake status of coral

Directly mounted flush against the arm with all wires running directly through the arm to the end effector

Single Falcon 500 mounted on the arm to run

Utilizes 9mm HTD belts on 3D printed 18T pulleys powering 5 rollers

3:1 reduction via pulleys from motor to first roller

Additional 3:1 reduction (9:1 total reduction) for algae

-

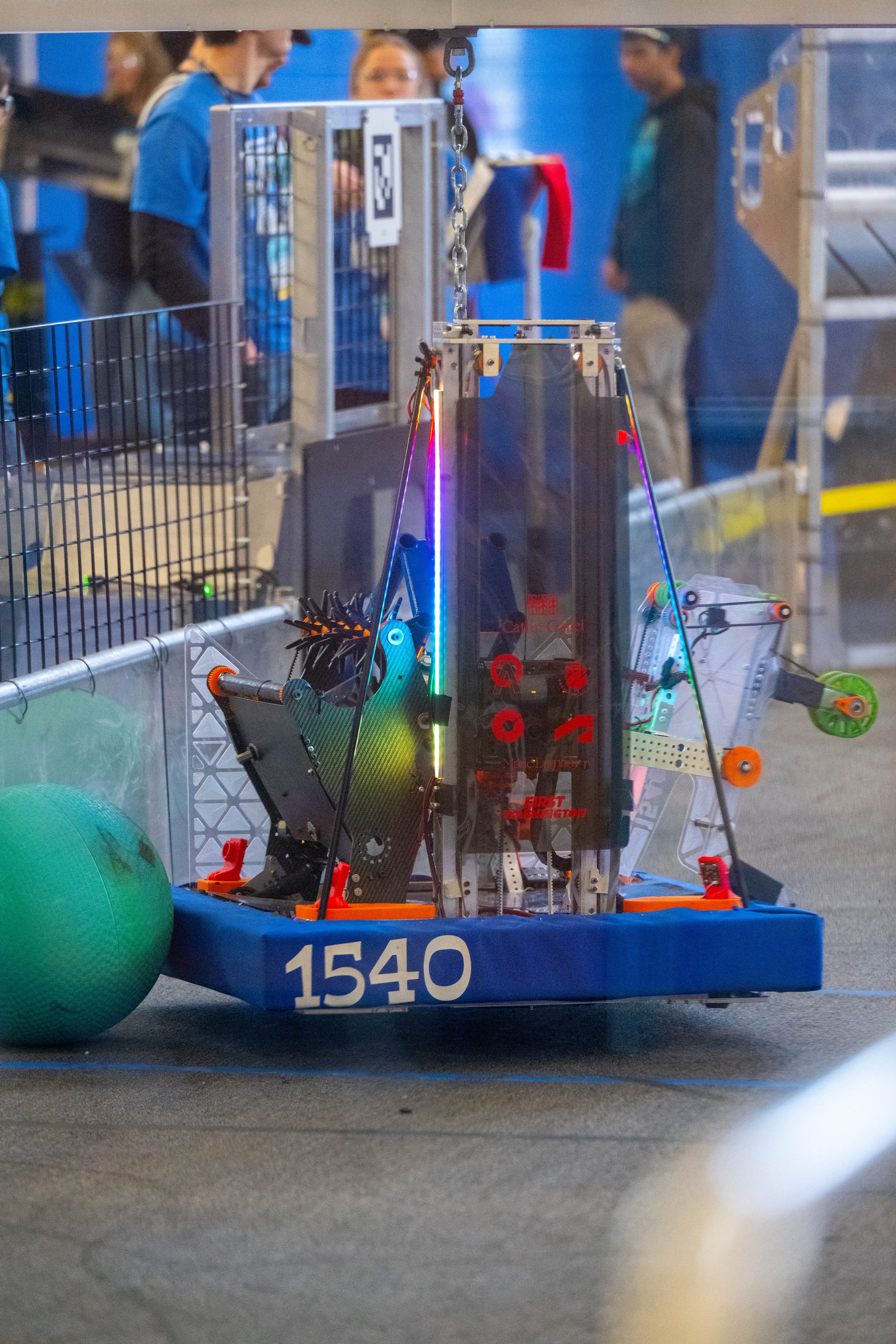

Lightened thin-wall tubing to minimize weight

¼” aluminum struts for front/back forces, aluminum tie rods with ball-end joints for side forces

Gearbox integrated into the frame as a strong structural foundation, powered by 2 Kraken X60s with a 3:1 reduction using a 24T HTD pulley to power belt

Continuous rigging, HTD 15mm Kevlar-backed belt in tubes power the arm

Bearings as idler rollers to guide belt, rated to survive loads well over operating 2300N load

Belts clamped with custom aluminum parts, belt bent over self and pressed together

Tensioning with WCP cams on the carriage

Constant force springs counteract gravity, allowing the extension to occur even faster

-

Everybot-inspired hooks, with modifications to better hold cage, remove unnecessary material

Self-adhesive tape on the inside face of hook to prevent cage slippage

Parametrically calculated height for ideal cage grabbing and pivoting

1” OD dead axle for structural support of the climbing structure

Powered by a Falcon 500 with FOC into 100:1 MAXPlanetary

Overall 360:1 reduction with sprockets, ensuring load is mainly on the chain and not gearbox

3D printed ratcheting system at motor output keeps the climb up after the match without power

Can be manually human-actuated to assist in declimbing and resetting the climb between matches

-

Field-centric swerve drive that uses 250Hz sensor reporting to maximize odometry accuracy

Fully automated reef alignment and collision avoidance ensures precise alignment to any point on the reef from anywhere on our side of the field with no driver input

Custom button board with layout of reef and intaking locations mimics field positioning, and allows drivers to select between different reef faces, scoring levels, and intaking areas for automatic alignment and driving

4 Arducam OV9281 cameras on each swerve module, connected to 2 Orange Pi 5s running Photonvision to detect AprilTags on the field

Autonomous trajectories generated with Choreo, which uses numerical optimization to find efficient paths that remain kinematically feasible